News and things to know

Insides from the plastics industry

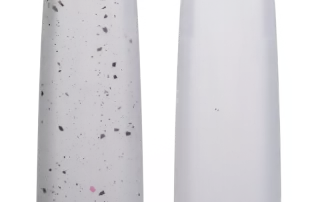

How black specks form in plastic

Various dissertations have investigated the formation of deposits and black specks on plastic melts in interaction with metal surfaces. According to these studies, the formation of deposits and the subsequent black specks caused by shearing cannot be […]

Remove black specks by cleaning with plastic granulate

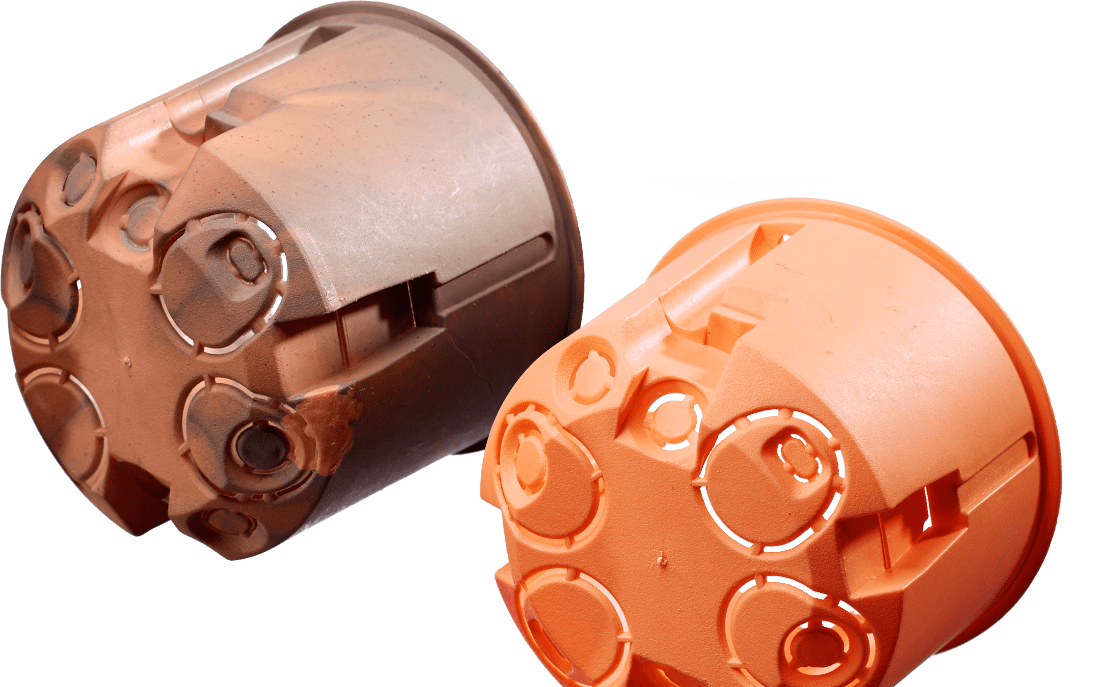

Remove black specks – by cleaning the hot runner nozzles!

The insulating areas of the hot runner nozzles are the biggest cause of black specks. Our per-tas-based cleaning granulate reaches and cleans these insulating areas.

The nozzles in the hot runner […]

Black specks in plastic (black scrap, black dots)

Do black specks in plastic also occur in your production?

Black dots in plastic – also known as black specks – are common phenomena in the plastics processing industry.

The most effective remedy: a cleaning granulate based on our “syn-tas” cleaner

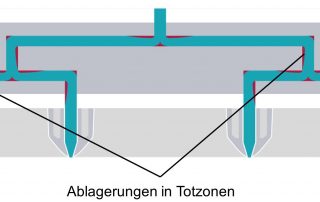

Deposits in the hot runner

Deposits in the hot runner:

Is chemical cleaning better than mechanical cleaning?

Compared to abrasive cleaning, chemical cleaning can be used to clean all metal surfaces in plastic processing machines and molds. Even in places where plastic material usually no longer flows […]

Grinding material + cleaning concentrate = cleaning granulate

Cleaning granulate produced in-house

An environmentally friendly and resource-saving cleaning process can only succeed with a cleaning concentrate. For example, the ground start-up scrap can be processed with a cleaning concentrate into a cleaning granulate. In this way, the raw material […]

Cleaning granulate for cleaning the hot runner

Cleaning granulate or cleaning concentrate for cleaning the hot runner

The chemical cleaning granulate from ver-rus reaches and cleans even the dead zones

Areas of non-flowing melt (dead zones) are found especially in the hot runner. In these areas, burnt plastic […]

Defective sealing surfaces as a reason for black specks

Sealing surfaces occur when two components meet. E.g. nozzle and cylinder head or cylinder head to cylinder (see illustration). Sealing surfaces must be absolutely flat, even and undamaged so that they seal without gaps at their boundaries. If this is […]

Cleaning concentrate in plastic granules

Advantages of cleaning concentrate

Every plastics processor is familiar with the problems involved both in the cleaning process and in changing colors or materials. Cleaning can be done very quickly, but usually it takes […]

Cleaning granulate = plastic granulate + cleaning concentrate

Cleaning granulate instead of cleaning concentrate?

The basis of a cleaning granulate in plastics processing is polyolefin. When changing color or material, e.g. from POM black to ABS beige, with a prepared cleaning granulate, the polyolefin comes into the system as […]

Wear as a cause of black specks

In addition to flow dead zones, damaged metal surfaces are also a cause of cost-intensive cleaning processes. Damaged metal surfaces can be found along the entire path of the plastic from the hopper to the cavity or to the exit […]