Cleaning granulate or cleaning concentrate for cleaning the hot runner

The chemical cleaning granulate from ver-rus reaches and cleans even the dead zones

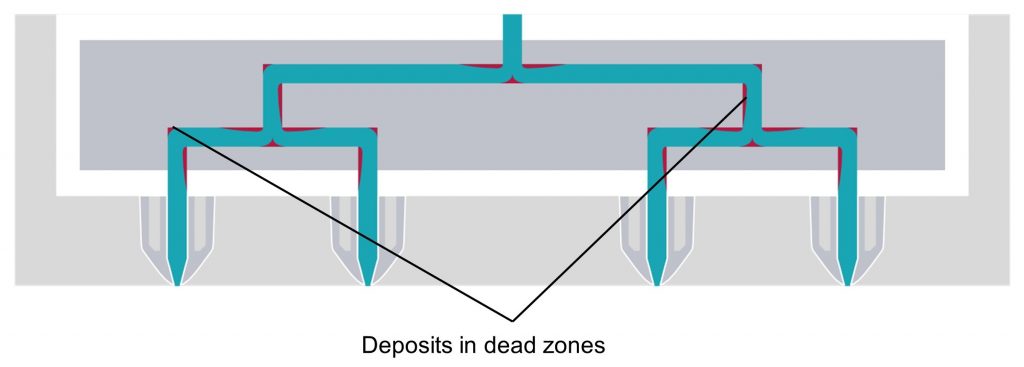

Areas of non-flowing melt (dead zones) are found especially in the hot runner. In these areas, burnt plastic builds up until it is carried away by the flowing melt. As a result, unnecessary scrap is generated. Of course, this is only the case if the deposit has not been removed before with a cleaning granulate!

Areas to be mentioned in this context:

- Distribution of the melt flow in multi-cavity molds

- Redirection of the melt flow to the nozzles

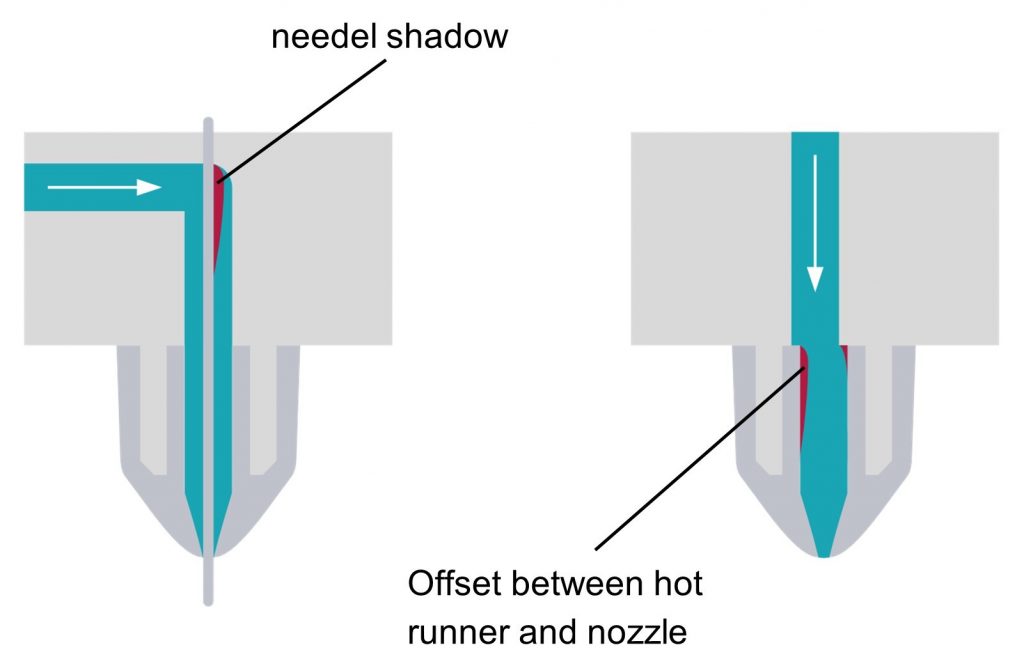

- Needle shadows in valve gate nozzles

- Transitions from the hot runner to the nozzles.

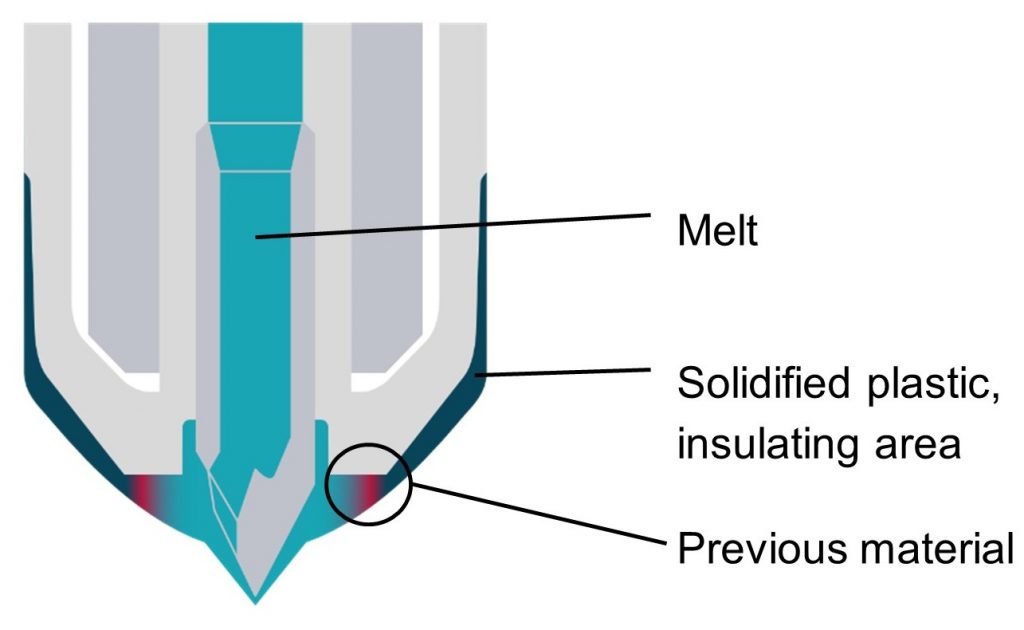

Contamination of the nozzles

The nozzles in the hot runner are the biggest sources of streaks and black spots (rejects). From the area where the solidified plastic is supposed to insulate the high temperatures of the nozzle from the cavity (insulating area), solidified, burnt plastic or the previous material is always carried away by the flowing melt.

Hardly anyone removes the insulating caps of the nozzles before each material color change. This is often very time-consuming, since in many cases the hot side has to be removed in order to dismantle the mold plate in the mold shop so that the insulating caps can be accessed. Even in cases where the mold plate can be dismantled on the machine, removing the insulating caps takes a lot of time.

Saving time with chemical cleaning granulate from ver-rus

This time can be saved if a foaming chemical cleaning concentrate is used.

By foaming up, the chemicals reach

- the insulating area

- penetrate into the deposits

- break them up from the inside

- loosen the deposits from the metal surfaces

- and rinse them out during restarting

These free areas are then occupied by the current melt and the previous material can thus no longer cause scrap.

Cleaning concentrate from ver-rus

ver-rus sells a cleaning concentrate which, in contrast to a cleaning granulate, can be flexibly varied in dosage and type of application. This is because our cleaning concentrate can be mixed with any plastic granulate to a cleaning granulate.

If you would also like to clean your machine quickly and efficiently with a cleaning granulate, please contact us!