Advantages of

cleaning concentrates

Universal and highly versatile in use

Cost benefits of ver-rus cleaning granules

The following savings can be achieved by using ver-us cleaning granulates and cleaning concentrates:

Savings on material costs

Adjusting the cleaning power: Save raw materials, time and therefore costs!

With cleaning concentrates from ver-rus, the required cleaning power can be adjusted to suit any degree of difficulty in the cleaning process. Simple cleaning processes require less added cleaning concentrate, while difficult ones require more. This means that simple and difficult colour and material changes / cleaning processes can be carried out in the same amount of time with the same amount of raw material. The costs for the cleaning material are thus adapted to the requirements.

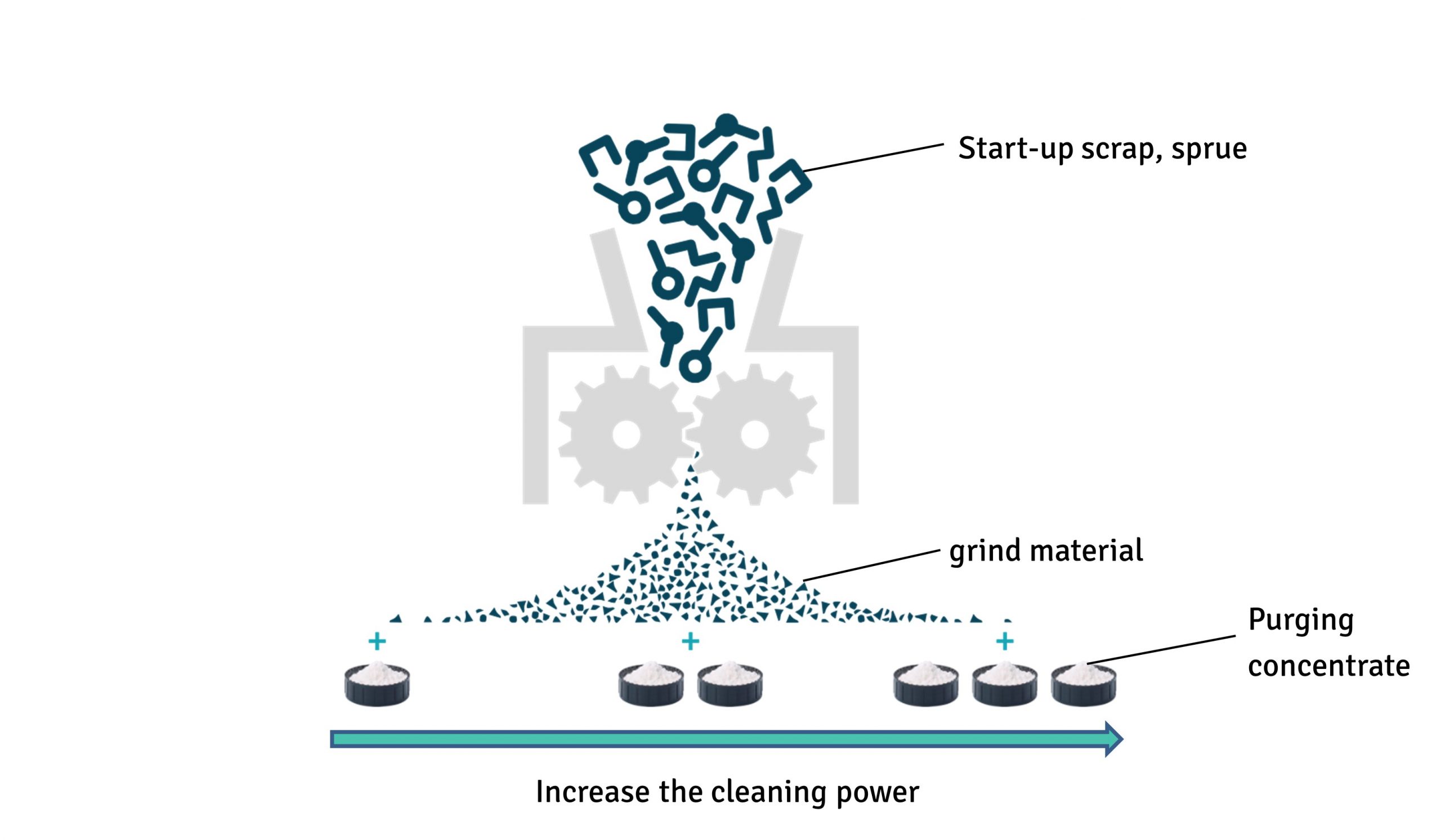

Furthermore, cleaning concentrate can also be mixed into regrind. Simply grind the start-up scrap and add the powdered concentrate – and the cleaning material is ready. In this way, original material is saved.

Lower personell costs

Clean dead flow zones: Where other cleaners can’t reach

Our foaming cleaning concentrates also reach and clean dead flow zones. The chemicals in the concentrates penetrate the deposits / burning residues and break them up from the inside.

This process effectively removes them from the metal surfaces and then purged them out. This technology enables efficient material and colour changes / cleaning processes within the shortest possible timeframe. This ultimately leads to significant cost savings in personnel resources.

Less scrap costs

No scrap due to black specks

Many plastics processors encounter the issue of black specks appearing in the plastic parts during production.

This is caused by burnt plastic that occurs in the flow dead zones. The plastic is exposed to high temperatures for an extended period, resulting in burning of the material. This creates multiple layers of burnt plastic. At a certain size, pieces of the burnt material are carried away by the flowing plastic melt and create black specks in the product. Because the ver-rus cleaning granules also clean the dead flow zones, no black specks can form and the scrap costs are zero.

Saving manufacturing costs

Speed up the manufacture of your products

At a certain size, the burnt plastic from the flow dead zones is carried away by the flowing plastic melt. This can result in hot runner nozzles becoming blocked or certain flow cross-sections becoming smaller.

This often results in longer cycle times. Longer cycle times mean higher manufacturing costs.

Less machine downtime and energy costs

Speed up your material changeover

Due to the cleaning of the dead flow zones and the possibility to adjust the cleaning force to the diffictulty of the material and colour change, the cleaning process can be carried out in the shortest possible time. This efficient process minimizes energy consumption and machine downtime, leading to cost savings.

Savings maintenance costs

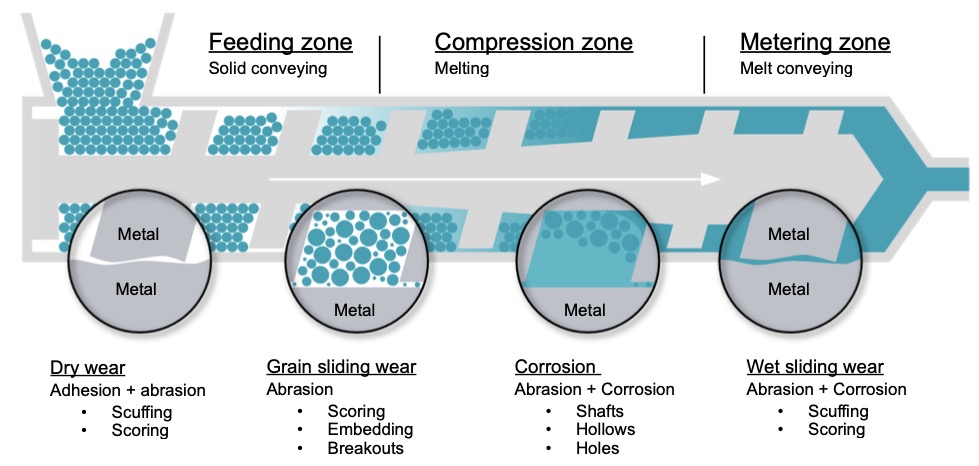

Less wear on your systems

The wear of screws, barrels, hot runners, extrusion dies, etc. is an enormous cost factor in plastics processing. There are a number of causes for wear and corrosion is one of them.

The cleaning concentrates from ver-rus clean all metal surfaces without causing corrosion. When cleaning with per-tas, the wear factor abrasion can also be excluded.

Lower storage and transport costs

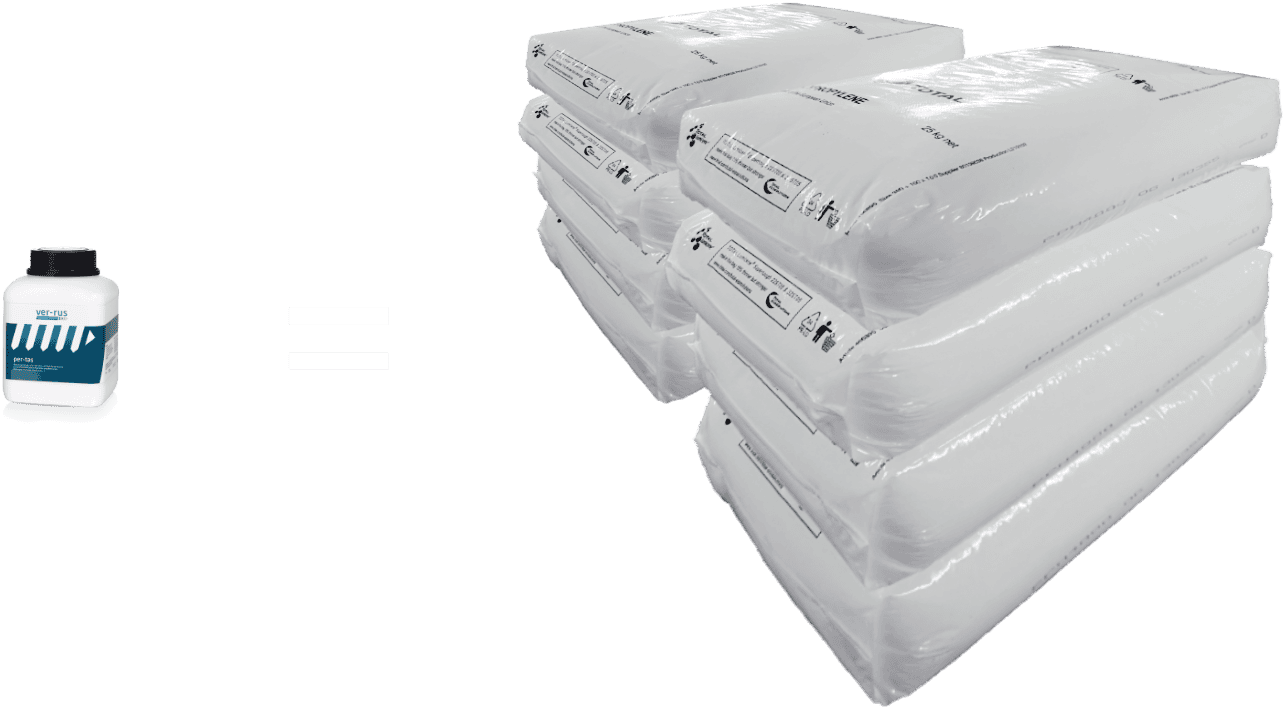

Up to 200 kg of cleaning granulate can be produced from 1 kg of cleaning concentrate!

No pallet spaces are required for cleaning granules, which saves storage costs. Similarly, only small packages (13 x 13 x 20 cm containers) need to be transported to you, rather than pallets. This also saves transport costs.

1 kg = 200 kg

Less CO2 emissions

Environmentally friendly and resource-saving

Every company is interested in saving CO2 costs. Every plastics processing company can make a contribution to this by using cleaning concentrates. Compared to cleaning granulates, the production of cleaning concentrates requires significantly lower energy consumption.

This is just one aspect of why cleaning concentrates generate lower CO2 costs than granulates. All the cost savings of a cleaning concentrate described above contribute to the fact that they generate significantly lower CO2 costs than cleaning granulates.

All advantages of ver-rus cleaning material at a glance

Cleans dead flow zones

Flow dead zones are reached and cleaned by foaming up

Adjustable cleaning power

By adding more (3.0%) or less (0.5%) of the concentrate depending on the degree of difficulty. Easy 0.5% Difficult 3.0%

Shortest cleaning processes

By cleaning the dead flow zones and adjusting the cleaning power

Lowest material consumption

Due to shortest cleaning processes

Gently cleans all surfaces

Due to the chemical, non-corrosive and non-abrasive effect of the cleaner (per-tas)

Low maintenance costs

Due to non-corrosive cleaning

Low storage and transport costs

As up to 200 kg of cleaning granulate / regrind can be produced from 1 kg of cleaning concentrate (container 13 x 13 x 20 cm)

No third component

As the cleaning concentrate is mixed in with the plastic, which is used for production. After cleaning, leave out concentrate and produce

Mixing costs for cleaning granulate

By adding the cleaning concentrate to the granulate or regrind (negligible)

Environmentally friendly and resource-saving

By using regrind (e.g. grind start-up scrap/sprues). Simply mix the regrind and cleaning concentrate to create a ready-to-use cleaning material.