Functionality of the cleaning process

Cleaning granulate for plastic processing operations

The problem:

1. The problem:

Deposits on the screw, in the hot runner and extruder

In all plastic processing operations (injection molding, extrusion, blow molding, etc.), deposits form on the metal surfaces that come into contact with the plastic melt.

Deposits in the hot runner

Deposits on the screw

Deposits in the extrusion die

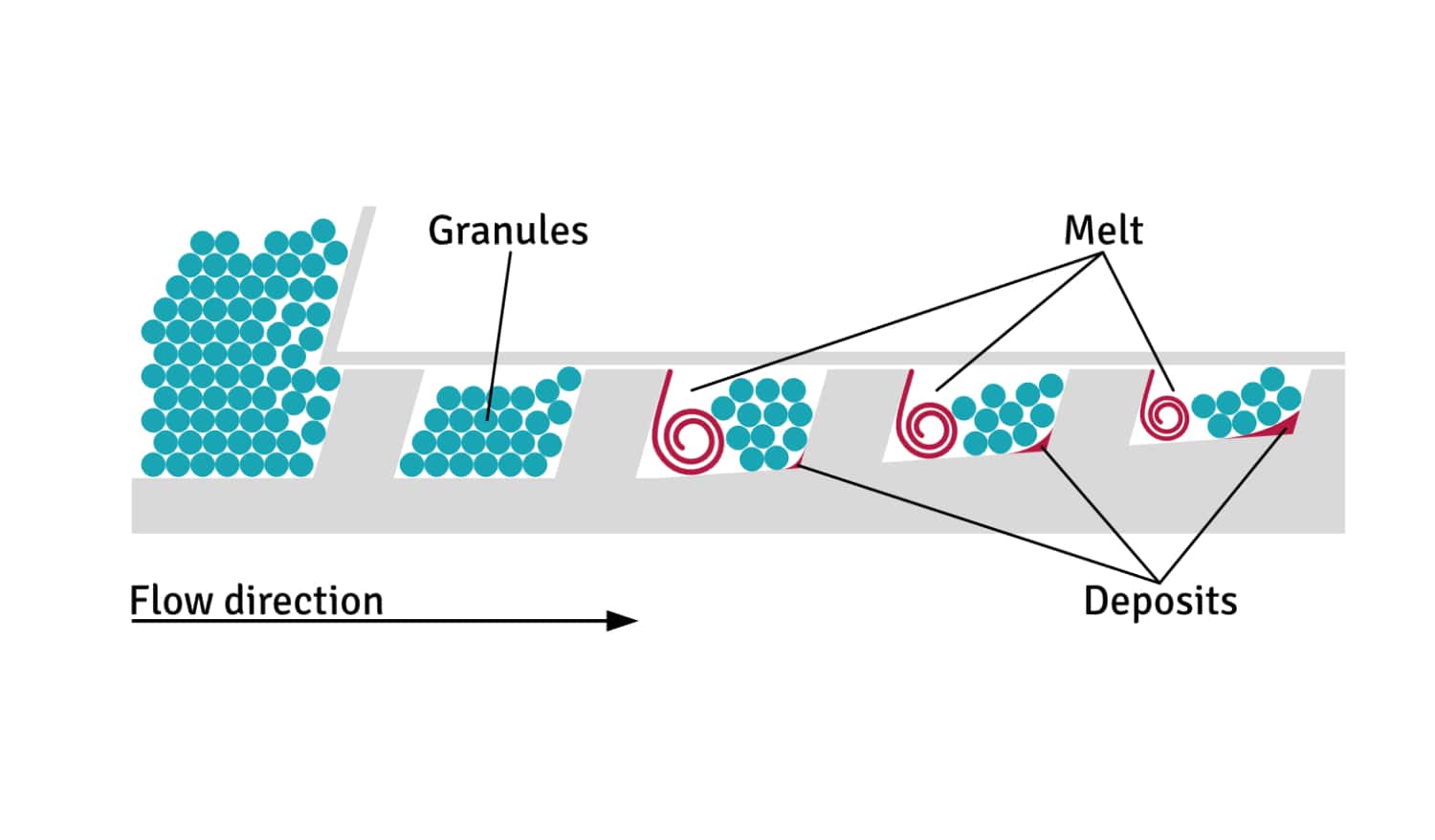

Particularly in the flow dead zones, the plastic is exposed to high temperatures for extended periods, causing burning of the material and build-up of deposits. At certain sizes the burned residues are carried away by the flowing plastic melt. This process leads to the presence of visible black specks in the molded part.

2. Our solution:

One cleaner for all applications

Chemical and abrasive cleaning

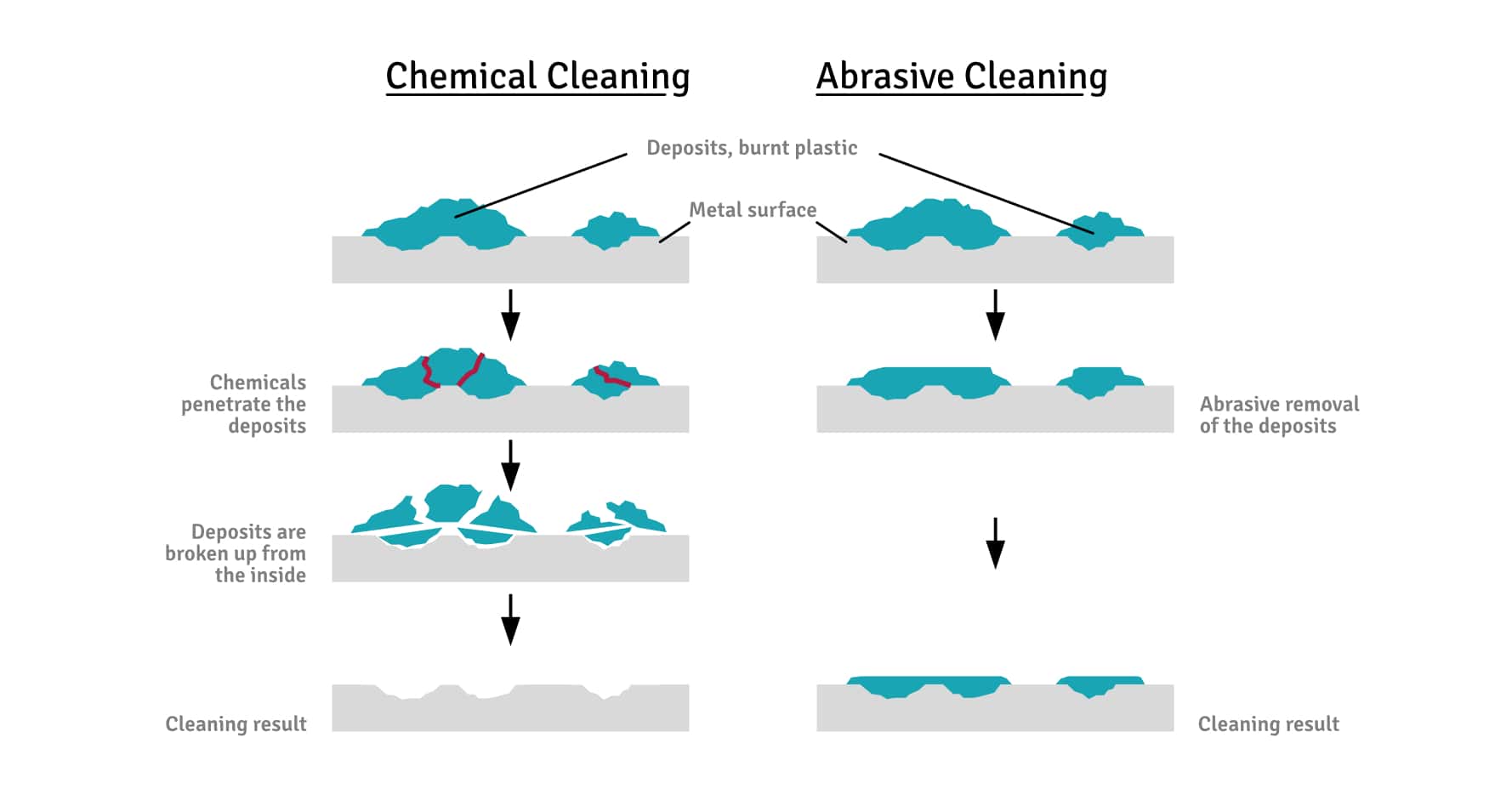

There are two ways to remove these deposits. They can be removed chemically or chemically and abrasively from the metal surfaces. ver-rus offers a purely chemical, non-abrasive cleaning option with the cleaning concentrate per-tas. Plastics processors who do not process abrasive plastics prohibit the use of abrasive cleaners and use per-tas. Other plastics processors who also process abrasive plastics clean chemically as well as abrasively with syn-tas.

Chemical cleaning

per-tas

per-tas is a chemical cleaning concentrate consisting of various chemicals.

During chemical cleaning, these chemicals penetrate the deposits and break them up from the inside. As a result they are loosened/ removed from the metal surfaces and then purged out.

The chemicals penetrating the deposits need a certain time to do so. For this reason, the cleaning process must be paused for approx. 5 minutes.

Abrasive and chemical cleaning

syn-tas

syn-tas is a chemical-abrasive cleaning concentrate. The chemical basis of syn-tas is per-tas. Due to the great success of our chemical cleaning concentrate per-tas, we have not changed the chemical components. Only abrasive substances have been added so that syn-tas utilizes both possible cleaning powers.

In abrasive cleaning, the deposits are removed mechanically layer by layer using abrasive components (emery effect). This means that the chemical forces act during the machine downtime of 5 minutes and the flowing melt provides the abrasive forces when the machine is restarted. Both forces achieve the best possible cleaning result.

Concentrate or granulate?

In addition to cleaning concentrates, ver-rus also produces cleaning granules.

The cleaning concentrates in powder form can be mixed with any plastic granulate and plastic regrind. This has the advantage that, for example, the cleaning granulate can be produced from PET granulate or PET flakes when only processing PET. This means that a foreign plastic does not have to be purged out with the PET after cleaning.

You can therefore choose the basis of your cleaning granulate/grinding material yourself. The required amount of cleaning concentrate can be determined in preliminary tests, or an average dosage of 2% can be added. There is no segregation, e.g. during transportation of the cleaning granulate, as the powder contains liquid chemicals so that it adheres to the granulate.

Another advantage of our cleaning granules is that the cleaning power can be increased at any time by adding more cleaning concentrate.

How it works:

3. How it works:

Cleaning flow dead zones

Deep effect cleaning due to foaming

Flow dead zones can be found in every plastics processing procedure (injection molding, extrusion, blow molding, etc.). Due to the foaming effect of our cleaning concentrates, the chemicals also reach and clean these flow dead zones.

The chemicals penetrate the deposits, break them up from the inside and remove them from the metal surfaces. The loose deposits are then purged out by the flowing plastic melt.

Intractable Deposits on the screw

Cost-efficient color and material changes as well as cleaning processes are always a major challenge for every technician in plastics processing. They often take several hours or even days and cause high costs.

One cause of these long cleaning processes is deposits on the screw. There are also flow dead zones in the screw base. As in all other dead zones, the plastic is exposed to high temperatures for too long, burns, builds up layer by layer and from a certain size is carried away by the flowing plastic melt (black specks).

Deposits on the screw

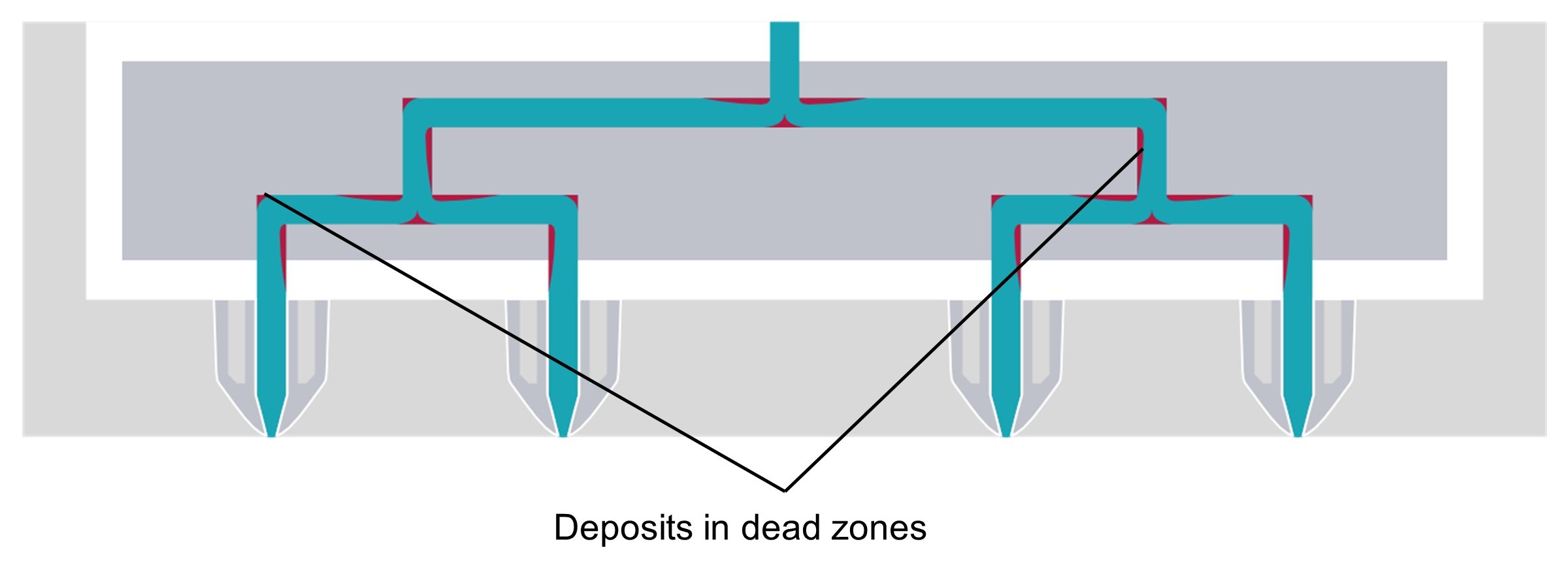

Dead zones in the hot runner during injection molding

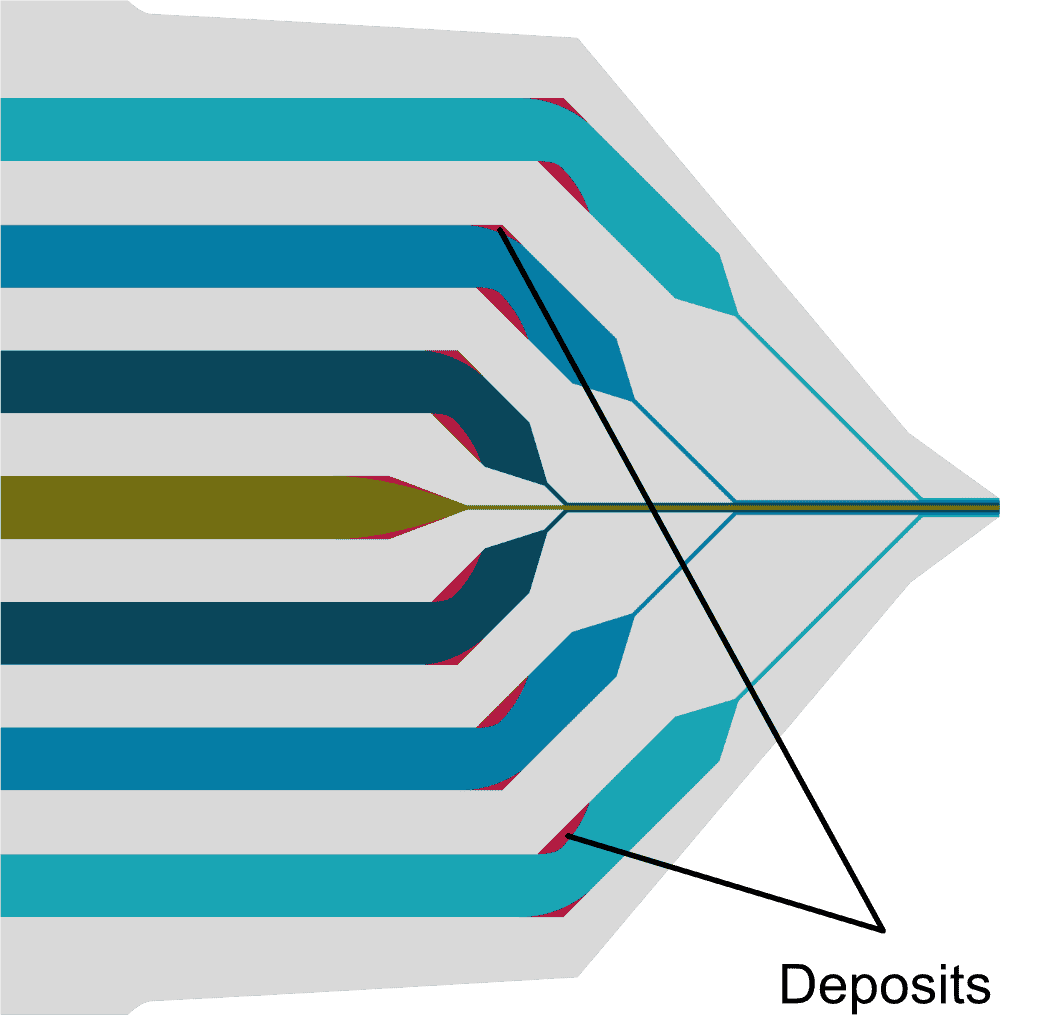

Especially in the hot runner there are some areas of non-flowing melt (dead zones).

Burnt plastic also builds up in these areas until it is carried away by the flowing melt and produces scrap.

The following areas should be mentioned here:

- Distribution of the melt flow in multi-cavity molds

- Redirection of the melt flow to the nozzles

- Needle shadows with valve gate nozzles

- Transitions from the hot runner to the nozzles

Deposits in the hot runner nozzles

The nozzles in the hot runner are the biggest cause of streaks and black specks. Solidified, burnt plastic or previous material is repeatedly carried away from the insulating area by the flowing melt. Removing the insulating caps of the nozzles before a material/color change is often quite complex and time-consuming due to the disassembly of mould parts.

This time can be saved if chemical cleaning granulates/concentrates are used. The foaming action of these cleaning agents causes the solidified plastic to dissolve and be purged out, creating a free area that can then be filled with the actual melt, thus eliminating the potential for scrap.

Material deposits in the extrusion

Cleaning granulate against material deposits in the extrusion process

Even in extrusion dies the plastic melt must be redirected. Flow dead zones occur at these points. As in all flow dead zones in plastic processing, the plastic burns and forms deposits that build up layer by layer.

At certain sizes the burned residues are carried away by the flowing plastic melt. Black specks or even cent-sized lumps can then be seen in the extrudate.

Examples from the plastics industry

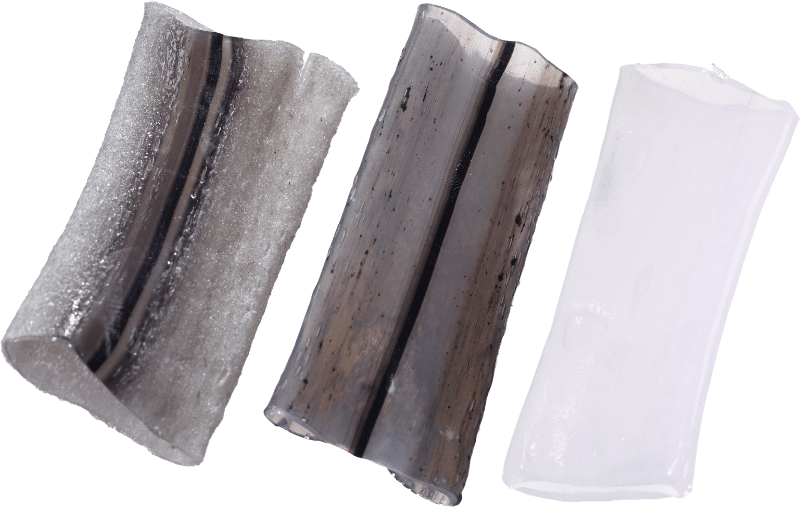

Screw and cylinder

These deposits were no longer visible after the cleaning process.

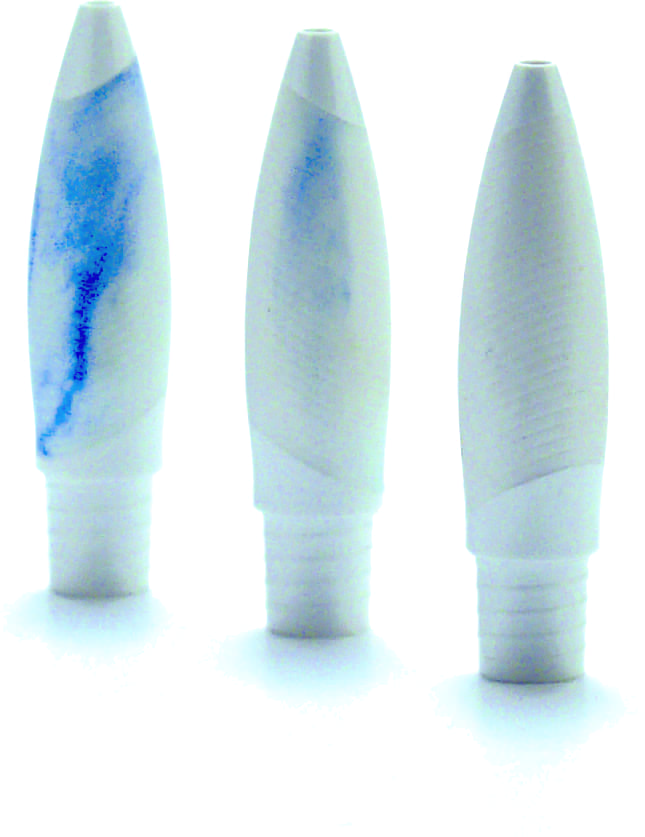

Injection moulding

In just a few cycles, colour changes such as this one from blue or red to white could be carried out with our cleaning concentrate per-tas.

Every injection moulding company is familiar with the annoying black specks. We have also been able to achieve rapid success in such cleaning processes with our cleaning concentrates and cleaning granulates.

Even clogged hot runner nozzles could be cleaned in a very short time and a shut-down cavity reactivated.

Extrusion

Extrusion screws and extrusion dies could be cleaned in a very short time.