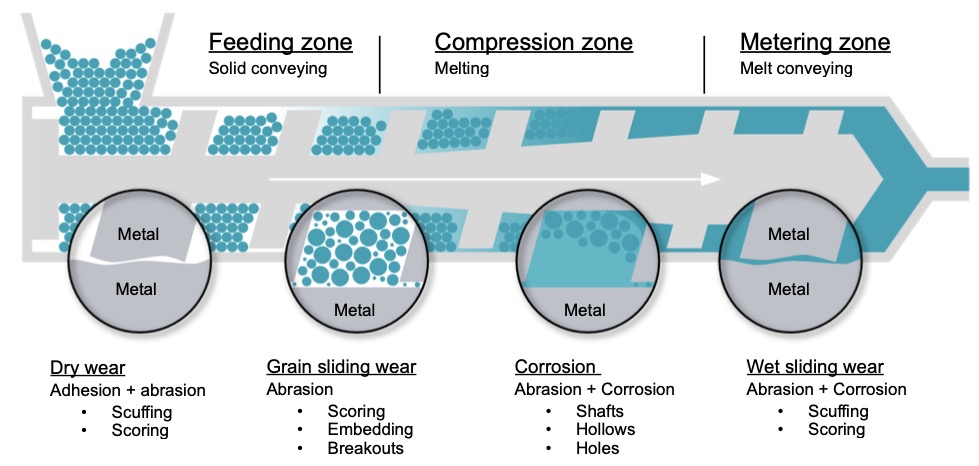

In addition to flow dead zones, damaged metal surfaces are also a cause of cost-intensive cleaning processes. Damaged metal surfaces can be found along the entire path of the plastic from the hopper to the cavity or to the exit extrusion die. They are caused, for example, by abrasive batches. For example, the hardness of titanium dioxide (white color batch) is 2400 HV and that of refined steel surfaces is 750 HV. According to this the metal surfaces are exposed to abrasive wear. Likewise, corrosion is a cause of occurring damage to the melt-bearing metal surfaces. Corrosive additives such as flame retardants, UV stabilizers, acid residues, antistatic, … damage the surfaces during processing. This abrasive/ corrosive wear leads to scores, holes, cracks, … in the metal surface. The plastic melt settles in these damages, burns, and builds up to a certain size until it is carried out by the melt flow, thus making the molded part unusable as a black spot.