Deposits in the hot runner:

Is chemical cleaning better than mechanical cleaning?

Compared to abrasive cleaning, chemical cleaning can be used to clean all metal surfaces in plastic processing machines and molds. Even in places where plastic material usually no longer flows (dead zones).

Deposits in the hot runner become black specks

Dead flow zones are present in every plastics processing operation, such as injection molding or extrusion. Deposits form in these flow dead zones because the plastic in the dead zones is exposed to high temperatures for too long. The plastic burns and deposits on the metal surfaces of the dead zones. These deposits build up layer by layer and, once they reach a certain size, parts of them are carried away by the flowing melt and get into the components. These are the black specks that every plastics processor is familiar with and which render the components unusable.

How does an abrasive cleaning granulate work?

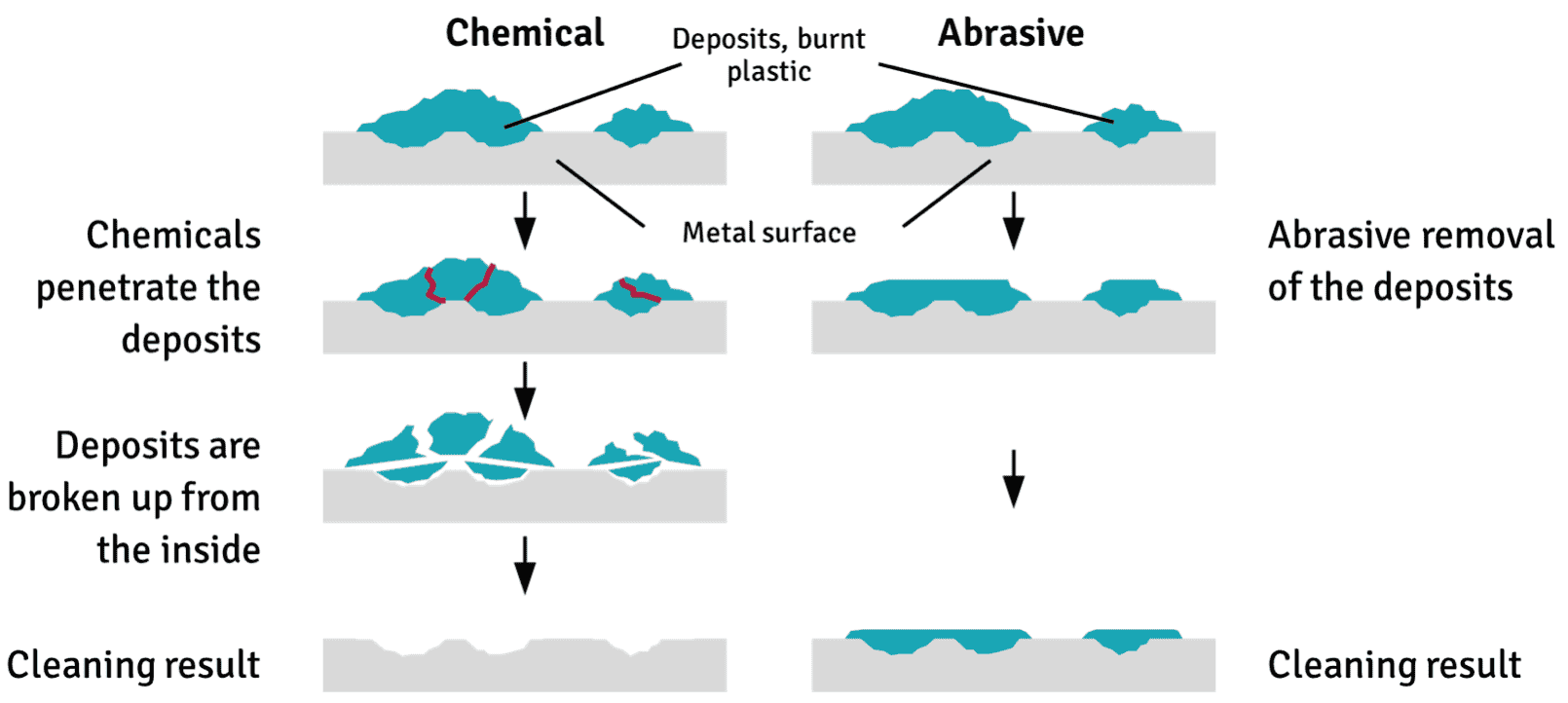

As the name suggests, abrasive cleaning uses abrasive elements such as glass fibers. These abrasive elements are located in the cleaning granulate and therefore in the flowing plastic melt. As the abrasive melt flows over the deposits, they are removed layer by layer. They are therefore removed mechanically, as with sanding. This mechanism therefore only works in the area of flowing melt.

Solution with chemical cleaning concentrate

An abrasive cleaning granulate does not work in the dead zones, so only a foaming chemical cleaner can help. Due to the foaming effect, it reaches the flow dead zones. The chemicals in the chemical cleaner require a short reaction time (the machine is left for approx. 5 minutes). During this time, the chemicals penetrate the plastic deposits and break them up from the inside. After the machine is restarted, the deposits loosened from the metal surfaces are rinsed out.

Chemical cleaning therefore cleans all metal surfaces! Abrasive cleaning, on the other hand, only cleans metal surfaces in the area of the melt flow.