Cleaning granulate produced in-house

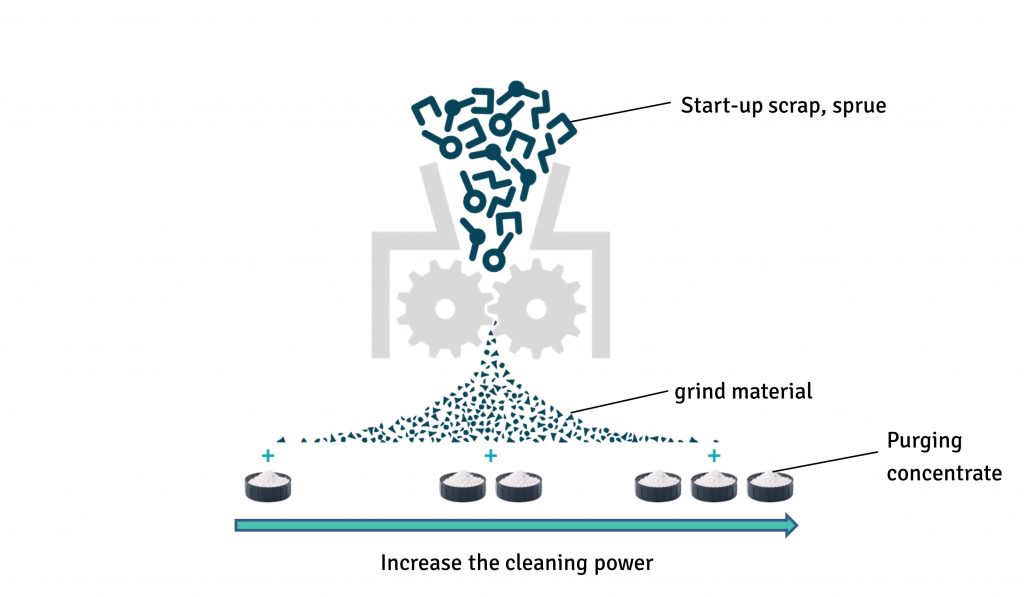

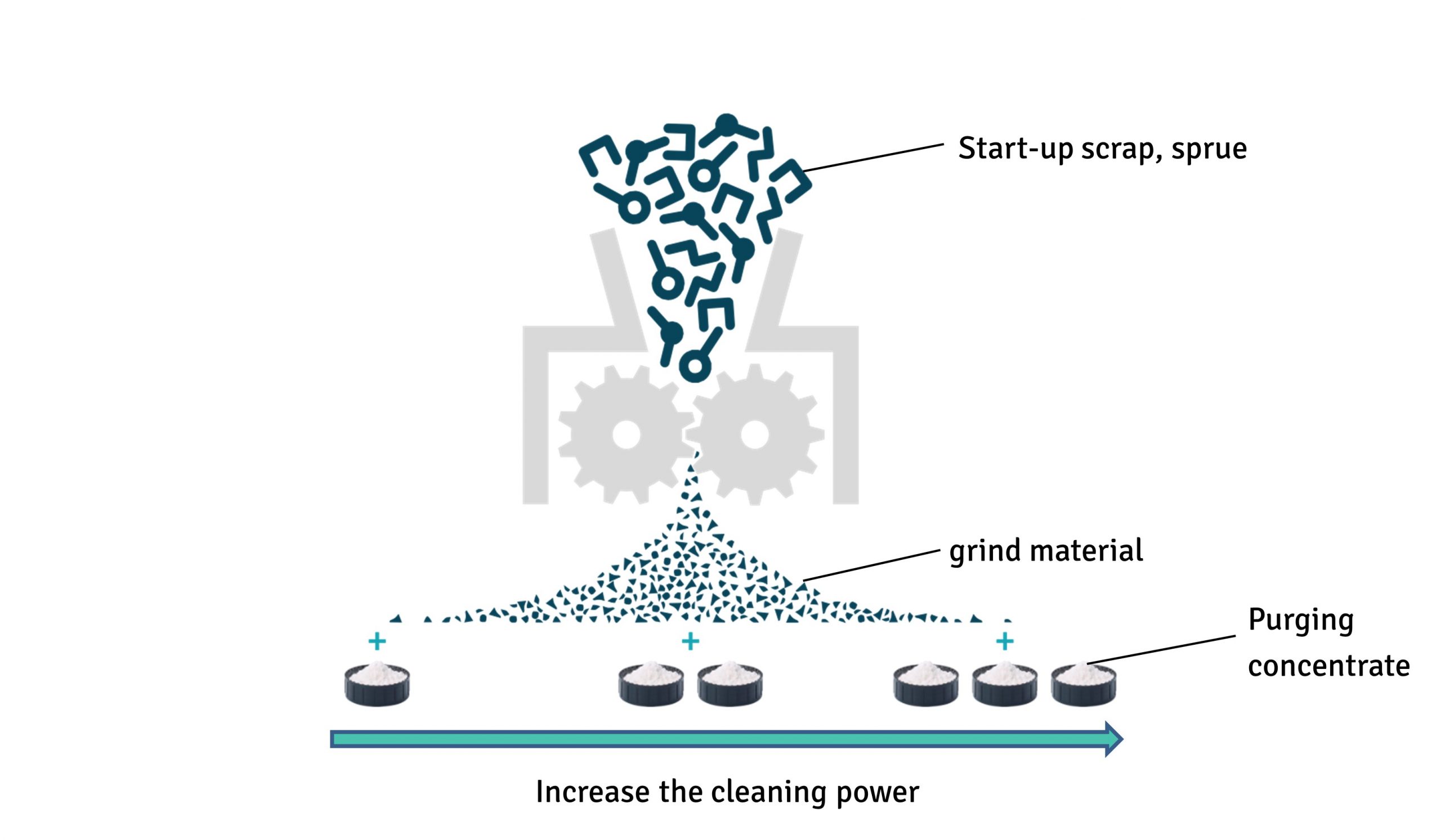

An environmentally friendly and resource-saving cleaning process can only succeed with a cleaning concentrate. For example, the ground start-up scrap can be processed with a cleaning concentrate into a cleaning granulate. In this way, the raw material (granulate) is saved and the start-up scrap does not have to be disposed of at high cost.

The required cleaning power can only be achieved with a cleaning concentrate.

Every plastics processor knows the difficult, long-lasting and costly color and material changes / cleaning processes. With a cleaning concentrate, the cleaning power can be increased in these cases. Simply add more concentrate to the regrind and the cleaning process is completed in the shortest possible time. Conversely, in simple cases, less cleaning concentrate can be used to save costs. In this way, simple and difficult cleaning processes can be carried out in the same time. Only the quantity of cleaning concentrate has to be adjusted. The quantity of the carrier material (regrind) thus also remains constant.

As a further environmental aspect, the lower transport and storage costs can be mentioned. Up to 200 kg of cleaning granulate can be produced from 1 kg of cleaning concentrate (container 13 x 13 x 20 cm).

With a chemical cleaning concentrate it is therefore possible to save

- time

- material

- energy

- manpower

- waste

- CO2

can be saved.

All these savings are a small contribution to environmental protection.