Chemical cleaning of machines and tools in plastics processing

Save raw materials, time and costs!

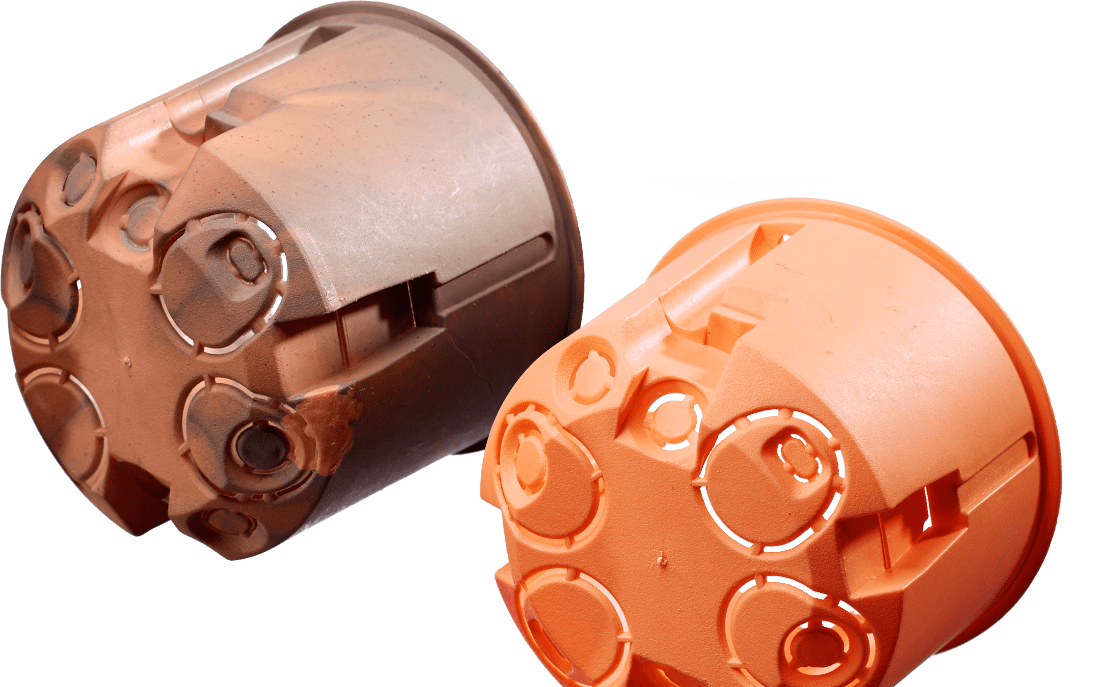

Cleaner for injection molding machines and extruders

Cost-effective cleaning – environmentally friendly and resource-saving.

Conventional cleaning processes used in the plastics industry are time-consuming and costintensive. Extruders, injection molding machines and blow molding systems including their tools have to be cleaned in a time-consuming process with a high loss of time and material until defect-free products are produced.

With our universally applicable cleaning concentrates, this cleaning process succeeds in a material-friendly manner and in the shortest time possible!

Concentrate instead of granules?

Why are cleaning concentrates from ver-rus better than comparable cleaning granules?

1.

Adjustment of the cleaning power: Save raw materials, time and thereby costs!

With the powdered cleaning concentrates from ver-rus, you can adjust the required cleaning power individually to each cleaning process yourself. Simple cleaning processes require less cleaning concentrate, difficult ones more. In this way, simple and difficult color and material changes / cleaning processes are finalized at the same time with the same amount of material.

The costs for the cleaning material are therefore adapted to the requirements.

2.

Cleaning of flow dead zones: Where others can’t reach!

Our chemical, foaming cleaning concentrates also reach and clean the flow dead zones. The chemicals of the concentrates dissolve the deposits/combustion residues from the metal surfaces which are then purged out. This saves time and material with the fastest material and color changes.

Scrap costs are reduced and due to the non-abrasive/corrosive effect of the ver-rus concentrates, the surfaces of the screw, barrel, hot runner and mold are also protected and their service life increased.

Advantage: Cost saving!

Advantages of the cleaning concentrates for self-mixing of ver-rus:

Quick color and material changes/cleaning

Lower energy, machine downtime, personnel and material costs

Lower maintenance costs

By gentle non-abrasive/corrosive cleaning of metal surfaces

Lower storage and transport costs

Up to 200 kg of cleaning material can be produced with 1 kg of concentrate (13x13x20 cm)

Our cleaning products

ver-rus

Cost-effective entry with strong cleaning power

per-tas

Optimized efficiency for all applications

Based on these two products, special cleaners can be developed according to your requirements and tailored for the needed application. — Contact us!

Prepared cleaning material

On request, we can supply our cleaning products on the basis of any granular/grinding material (PVC, PE, PP, POM, ABS, SAN, PC, PA, PEEK,…) with any required cleaning power (more or less cleaning concentrate).